Adhesive Dispensing Systems

In the current market, there are two primary MMD or Meter Mix Dispense options present for adhesive dispensing systems. Knowing about the two is essential to give you a clear idea when it comes to choosing the most suitable solution for your specific requirements. Should you be looking to set up an MMD machine, the information below should be useful for you.

STATIC MIXER

For the static type of mixer, it does not depend on the movable components for mixing the products. What it does instead is utilize the force from the material as it is pushed throughout the mixture. This splits and blends the mixture until the mixture becomes completely uniform. Static mixer machines are resilient towards air bubbles (meaning no air bubbles are formed). This saves the processing company time, as well as money. As for the static mixers, it is advisable to use Dow Corning/DOWSIL silicone pumps for the best results. Here, you meter the product by substituting/using rods with different strokes to get the desired output. Static mixers have come out to be a much more reliable option than the conventional manual MMD techniques. Additionally, these machines are easy to upkeep and low in price.

DYNAMIC MIXER

Dynamic mixer machines are dependent on the movable parts of the motor. It is an incredibly high-precision machine setup. The rotating component uniformly blends the mixture. These machines also often come equipped with a flushing port. This has a great advantage; you get easy access to drain the solvent right from the machine to restrict curing. You can rely on these machines should you be operating with more than one product(s) that has different viscosity numbers. This mixer also does the job way better than manually mixing, just like static mixers. These types of mixers are costlier options than their static counterparts.

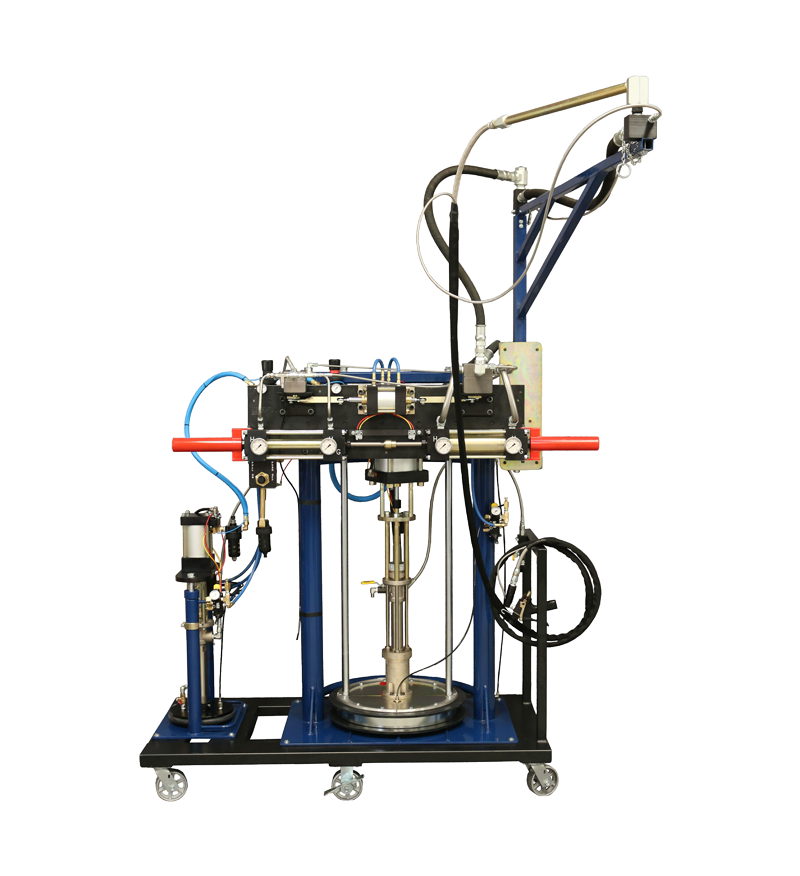

This is where the 55-gallon drum dispensing system comes to the rescue. Model 350 HC, 55 gallon, high flow, light to heavy viscosity, single component adhesive dispensing systems make the life of the operator easier.

CONCLUSION

To choose the right product, you need to assess the product volume that your company produces. Both can be great options for high liquid volume. While static machines add significant volume to the product, dynamic machines can be deployed to get a more well-mixed final product.